✨ Comprehensive Comparison of NIAZIT Joist and Chromite Joist ✨

This article presents a code-oriented and engineering-based comparison between the NIAZIT Open Web Steel Joist (OWSJ) system and conventional Chromite open web joists, focusing on concrete web elimination, 30–40% reduction in concrete consumption, slab dead load adjustment for ETABS modeling, support connections, and span capacity, in accordance with ISIRI 12977 and SJI 200-2015.

🔹 Top Chord Performance

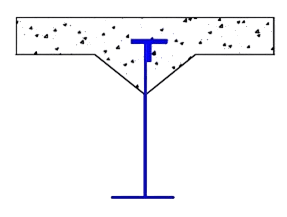

🔸 Chromite Joist (Open Web Steel Joist)

In Chromite joists, the top chord is typically made of angle sections. Since angle sections have a single-axis radius of gyration, they are highly susceptible to lateral buckling under compressive forces, particularly during concrete casting without shoring.

Important Note:

According to Clause 4-4 of Iranian Standard No. 12977, joists longer than 6.5 meters must use double symmetrical angles for the top chord. Failure to comply with this requirement is one of the main reasons for slab collapse during concrete pouring.

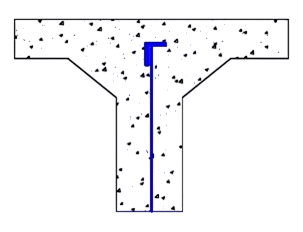

🔸 NIAZIT Joist (Joist Without Concrete Web)

In NIAZIT joists, the top chord is designed using a T-section from the beginning. Due to its symmetrical geometry and biaxial radius of gyration, the T-section demonstrates superior resistance to lateral buckling during construction and concrete placement.

The top chord can be accurately designed for all loading conditions:

Composite

Non-composite

With shoring

Without shoring

Non-composite condition refers to scenarios where the joist alone carries all dead and live loads without relying on concrete.

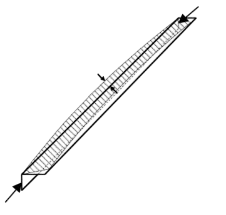

🔹 Web Member Performance (Structural Behavior)

🔸 Chromite Joist

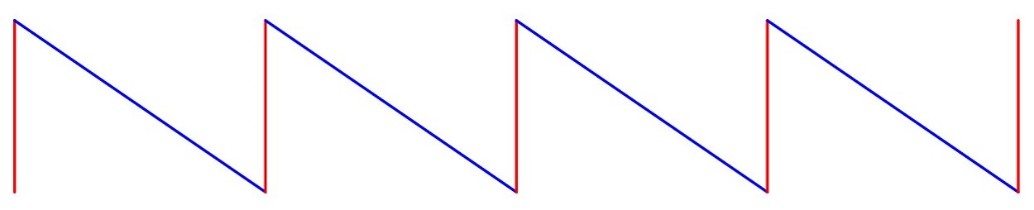

The web system consists of continuous zigzag rebars acting alternately in tension and compression. Each bend in the zigzag is simultaneously subjected to tensile and compressive stresses, resulting in stress concentration and long-term deflection, especially during and after concrete casting.

🔴 compression area

🔵 tenshion area area

🔸 NIAZIT Joist

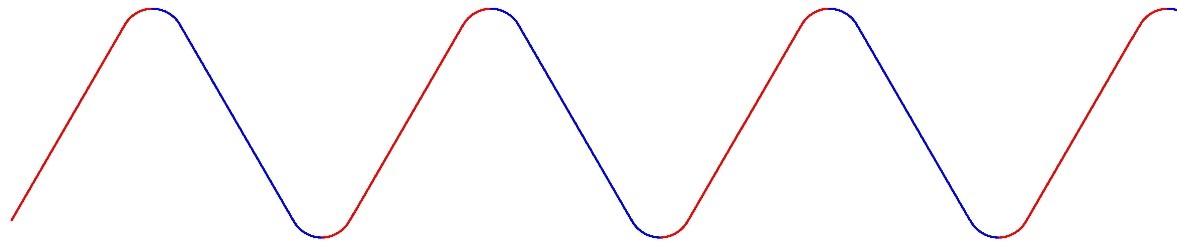

The web members are composed of separate vertical and diagonal steel elements, each specifically designed:

Vertical members resist compression

Diagonal members resist tension

The absence of bends and continuity eliminates stress concentration and allows:

Independent design of each member

Targeted strengthening where required

Improved structural efficiency

🔴 compression area

🔵 tenshion area area

🔹 Web Member Design & Analysis

🔸 Chromite Joist

After concrete hardening, the zigzag rebar is designed primarily based on shear control according to Clause 2-2-2-5 of Publication No. 543, requiring at least 25% of the support reaction. Due to continuity, local strengthening is not possible without increasing the entire rebar size.

🔸 NIAZIT Joist

Each web member can be analyzed and designed individually, allowing precise structural optimization. Local reinforcement is possible under special loading conditions without unnecessary material increase.

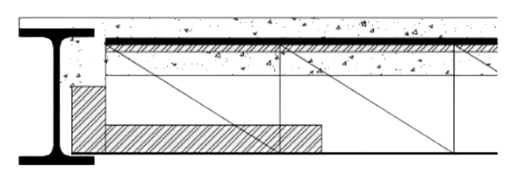

🔹 Concrete Web Evaluation

🔸 Chromite Joist

Concrete infill in the web often suffers from poor vibration and compaction, leading to reduced compressive strength. Under seismic excitation, cracked or poorly bonded concrete web significantly loses effectiveness, causing long-term slab deflection.

🔸 NIAZIT Joist

By eliminating concrete from the web:

Dead load is reduced

Structural elasticity is increased

Seismic performance is significantly improved

🔹 Concrete Web in Joists (Economic Comparison)

🔸 Chromite Joist: Higher Concrete Consumption ❌

🔹 NIAZIT Joist: 30–40% Less Concrete Consumption ✅

Since NIAZIT joists are designed without concrete in the web, there is a substantial difference compared to Chromite open web joists, both in terms of slab dead load and overall construction cost.

Concrete volume in Chromite open web joists

minus

Concrete volume in NIAZIT joists without concrete web

equals

Net concrete consumption difference

**Sample Table: Reduction of Slab Dead Load for ETABS Modeling(Assumed Concrete Haunch Dimensions = 8 × 25 cm)** | ||

Open Web Joist Arrangement (Chromite) | Joist Spacing (cm) | Dead Load Reduction (kg/m²) |

| Single Joist | 50 | -96 |

| Double Joist | 50 | -192 |

| Single Joist | 70 | -69 |

| Double Joist | 70 | -138 |

Weight Reduction FormulaConcrete Unit Weight × (Joist Spacing ÷ Haunch Concrete Area) | ||

Table: Reduction in Haunch Concrete Consumption Cost in NIAZIT Slab Compared to Chromite Slab(per 1,000 m² of Net Slab Area) | ||

| Open Web Joist Arrangement (Chromite) | Joist Spacing (cm) | Reduction in Concrete Volume in NIAZIT Slab (m³) |

| Single Joist | 50 | 40 |

| Double Joist | 50 | 80 |

| Single Joist | 70 | 29 |

| Double Joist | 70 | 58 |

Cost Difference FormulaDaily Concrete Unit Price × (Joist Spacing ÷ Haunch Concrete Area)= Concrete Cost Difference per Square Meter of Slab | ||

Engineering Note (ETABS Application)

The above values represent the reduction in slab dead load resulting from the elimination of haunch concrete in the NIAZIT Joist System compared to the conventional Chromite open web joist system.

These values may be directly applied in ETABS as a negative dead load adjustment (ΔDL) for slab load definitions.

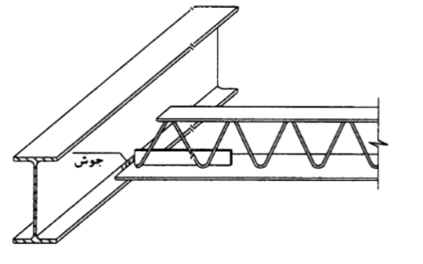

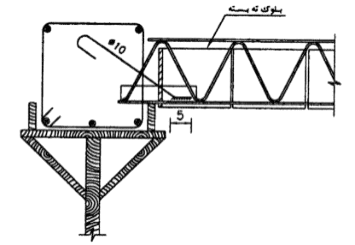

🔹 Joist Connections and End Fixity at Supports

🔸 Chromite Joist

These connection details often result in limited fixity and reduced structural reliability, especially under construction-stage and seismic loading.

In steel frame structures, the first zigzag web member of a Chromite joist is subjected to high force demand and therefore requires significant strengthening.

Chromite joist connection in reinforced concrete frame structures

In unhaunched conditions, the connection capacity is generally insufficient

Limited end fixity at supports

Reduced reliability under construction and seismic loads

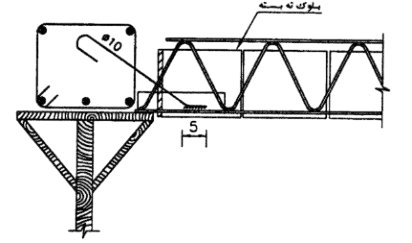

🔸 NIAZIT Joist

In the NIAZIT joist system, connections are designed as structural load-resisting details.

Use of vertical stiffener plates

Reliable force transfer at supports

Higher end fixity

Improved seismic performance

NIAZIT joist connection in steel frame structures (with vertical stiffener plate)

NIAZIT joist connection in reinforced concrete frame structures

🔹 Weight, Span & Execution

🔸 Chromite Joist

For spans above 7–8 meters:

Double joists are required

Continuous stiffening plates must be used

Double-angle top chords are mandatory

Any deviation from these requirements voids compliance with Standard 12977.

🔸 NIAZIT Joist

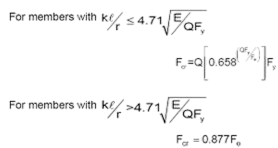

Designed in accordance with SJI 200-2015, Clause 5.5.2.1:

Spans up to 18.3 meters are permitted

Longer spans achievable with bolted connections

No need for double joists

Reinforcement applied only where structurally required

Optimized joist spacing:

Residential spans up to 9 m → 70 cm

Longer spans → 50 cm

🔹 Final Conclusion

For short spans (≈4 m), the weight difference between Chromite and NIAZIT joists is minimal. However, in medium and long spans, NIAZIT joists offer superior performance in terms of:

Weight reduction

Span capacity

Structural safety

Code-compliant design

Construction efficiency