NIAZIT Composite System

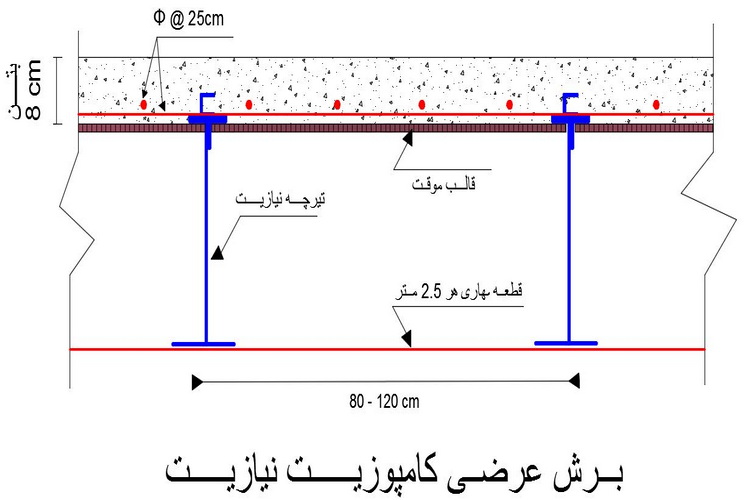

NIAZIT Composite System is a modern, engineered structural floor system designed as an advanced solution for composite slabs in both steel and concrete structures. In this system, traditional secondary steel beams are replaced by NIAZIT steel joists combined with temporary formwork, resulting in improved structural performance, reduced material consumption, and easier execution.

Introduction to NIAZIT Composite System

In the NIAZIT Composite System, shear connectors—typically in the form of angles or channels—are welded to the top chord of the NIAZIT steel joist. Since steel joists are used instead of conventional steel beams, the system can be safely applied to both steel and reinforced concrete frames without structural limitations.

Unlike the NIAZIT Deck System, which utilizes permanent galvanized steel decking, the NIAZIT Composite System employs temporary formwork, enabling a more economical and faster construction process.

Main Components of the NIAZIT Composite System

1. Top Chord

The top chord of the NIAZIT joist is formed by a T-section and:

Acts as the primary compression member of the joist

2. Web Members

The web consists of vertical and diagonal members made of plain or deformed reinforcing bars:

Vertical members → compression elements

Diagonal members → tension elements

Welded to both top and bottom chords

Responsible for transferring shear and axial forces

3. Bottom Chord

The bottom chord is composed of:

Steel flat bar (PL), or

ST37 steel plate

and functions as the main tension member of the joist.

4. Reinforcement Elements (Shear Connectors)

Reinforcement components are considered strengthened sections of the joist and:

Are designed based on critical structural conditions

Increase shear and flexural capacity

Are applied where required by structural calculations

5. Assembly Rebar

Assembly rebar is a non-load-bearing element that:

Is used in concrete frames to facilitate joist placement during concreting

Is not required in steel frames due to nominal welding of the bottom chord to the main beam

6. Shear Studs

In NIAZIT joists:

Shear studs are typically T-shaped angle connectors

Welded to the top chord

Ensure full composite action between the concrete slab and the steel joist

General Configuration of the NIAZIT Composite System

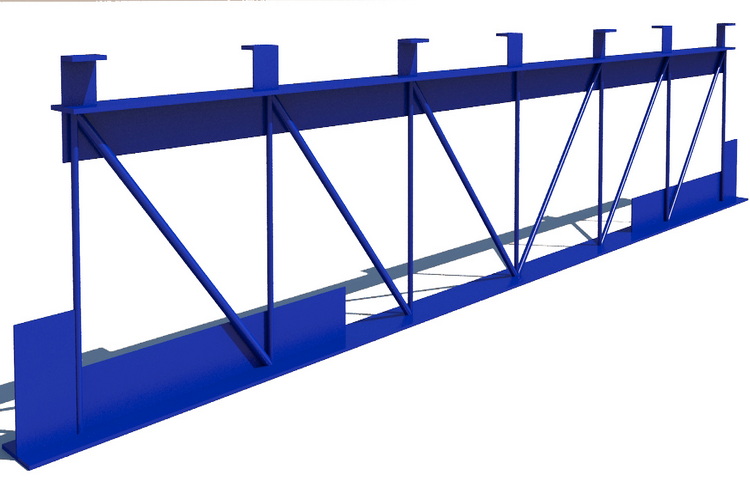

NIAZIT composite joist used in steel structures (Figure 1)

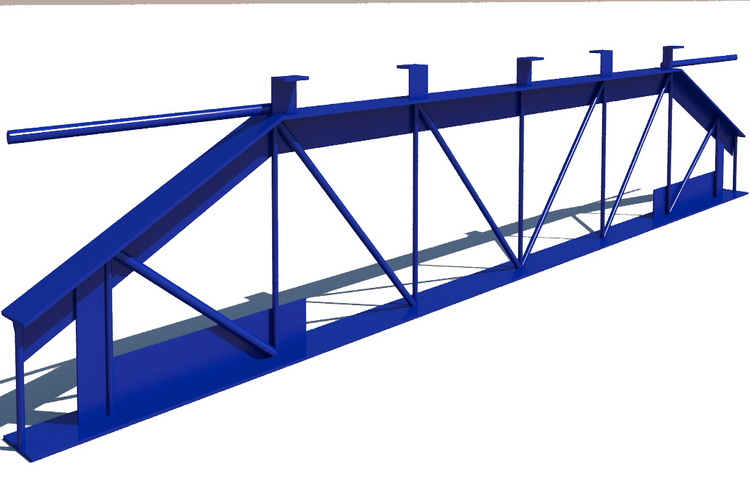

NIAZIT composite joist used in concrete structures (Figure 2)

Key Features and Advantages

Compatible with both steel and concrete structural frames

Reduced steel and material consumption compared to traditional systems

High execution speed due to temporary formwork

Easy passage of mechanical and electrical services within the slab depth

Flexible and fully engineered design for various project types

These advantages make the NIAZIT Composite System an ideal solution for residential, commercial, and industrial projects, improving execution efficiency while reducing overall construction costs.

Applications of the NIAZIT Composite System

Residential and apartment buildings

Commercial projects requiring fast construction

Industrial buildings and warehouses

Key Differences Between NIAZIT Composite System and Conventional Composite Floors

| Criterion | NIAZIT Composite System | Conventional Composite Floor | Description |

|---|---|---|---|

| Load-bearing slab reinforcement | Not required | Required | Eliminates additional rebar costs |

| Secondary beam type | Steel joist | Steel beam | Lighter floor structure |

| Concrete slab thickness | Reduced | Usually greater | — |

| Services passing through beams | Possible | Limited | Steel beams restrict service routing |

| Suitable for concrete frames | Yes | No | Fully adaptable system |

| Economical span range | Unlimited | Limited | Conventional systems are uneconomical over ~7 m |

| Floor vibration in long spans | Negligible | More likely | Larger beam spacing increases vibration risk |

Conclusion:

The NIAZIT Composite System is more suitable for large-scale and complex projects due to reduced material usage, faster construction, and optimized costs, while conventional composite floors are generally used in shorter spans with standard execution requirements.

General Configuration of the NIAZIT Composite System

NIAZIT composite joist used in steel structures

NIAZIT composite joist used in concrete structures

Key Features and Advantages

Compatible with both steel and concrete structural frames

Reduced steel and material consumption compared to traditional systems

High execution speed due to temporary formwork

Easy passage of mechanical and electrical services within the slab depth

Flexible and fully engineered design for various project types

These advantages make the NIAZIT Composite System an ideal solution for residential, commercial, and industrial projects, improving execution efficiency while reducing overall construction costs.

Applications of the NIAZIT Composite System

Residential and apartment buildings

Commercial projects requiring fast construction

Industrial buildings and warehouses

Key Differences Between NIAZIT Composite System and Conventional Composite Floors

| Criterion | NIAZIT Composite System | Conventional Composite Floor | Description |

|---|---|---|---|

| Load-bearing slab reinforcement | Not required | Required | Eliminates additional rebar costs |

| Secondary beam type | Steel joist | Steel beam | Lighter floor structure |

| Concrete slab thickness | Reduced | Usually greater | — |

| Services passing through beams | Possible | Limited | Steel beams restrict service routing |

| Suitable for concrete frames | Yes | No | Fully adaptable system |

| Economical span range | Unlimited | Limited | Conventional systems are uneconomical over ~7 m |

| Floor vibration in long spans | Negligible | More likely | Larger beam spacing increases vibration risk |

Conclusion:

The NIAZIT Composite System is more suitable for large-scale and complex projects due to reduced material usage, faster construction, and optimized costs, while conventional composite floors are generally used in shorter spans with standard execution requirements.