Abstract

This kind of composite joists performs in such a way that in addition to complete omission of welding in the connections of the joist, by making use of extending the middle threaded rebar along with it upwards and fastening nut above it, it is applied as a stud in the ceiling. Furthermore, it is designed in such a way that in addition to the aforesaid specifications, execution of joist in the ceiling could be made with types of permanent and provisional molds.

Technical Field

The present invention is the technical field of joists, ceilings and floors of buildings which act as the gravitational load-bearing system.

Background Art

Checking CJ-Series joist system from Open Web Steel Joist (OWSJ) Association from America: By reviewing the background of open web steel joist implemented by American OWSJ Association since 1923, the required standards are compiled for calculation of this type of joists derived from ACI and AISC regulations, and among the relevant series, CJ-Series system could be named in accordance with SJI 200-2015 standard concerning the joists with composite performance. Meanwhile, other various models could be observed in Wikipedia and steeljoist.org.

Checking the joists with nut and bolt connections: By studying the models searched in international patent registration sites such as googlepatent, patentscope, espacenet, uspto, the cases such as CA2191133A1, US9587401B1 are seen concerning splice between two joists, as well as the items such as CA2409645C, KR100665959, US2002046534A1, US3106995A are seen that none of the said plans are capable of composite simultaneous performance without welding connections of the joist on which the stud is installed, and no case of joists could be executed with types of permanent and provisional filling molds.

Checking the relevant domestic and foreign regulations: In terms of technical and executive calculations, the accredited domestic and foreign regulations such as Chapter 9, 10 and 6, Standard 12977, Standard 2909, Leaflet 543, Leaflet 151, of Iran National Construction Regulations, and ACI Circular, AISC Circular, Standards SJI 200-2015, Standard SJI 100-2020, have been reviewed.

Technical Problem

Concerning construction and assembly of the joists with bolt and nut joining, complexity of design and construction comparing simple truss, and making use of various shaped parts such as applying metal pipes, pressing and bending its two ends in vertical chord of joist as well as pressing and shaping steel strap in most components of joist, construction procedure is a time consuming activity in addition to extra expense are imposed and surplus nuts are used in construction of such kind of joists.

In execution of the joists with bolt and nut connections, in case they are implemented in the ceiling of deck, upon placing the deck sheet on the joists, the stud should be welded from deck sheet to upper chord of joist and/or screwed to a threaded stud which is a time-consuming, time-wasting and expensive actions besides regulating place of connecting stud from deck sheet and controlling welds at the end of stud.

For the execution of the joists with bolt and nut joining, the joists are designed in such a way that it is infeasible to use the covering molds among joists in order to execute concreting slab, and execution of such ceilings requires execution of deck sheet with high thickness and load-bearing.

Solution to Problem

Simplifying parts and designing joist in the form a simple truss: In this type of joist comparing the joists with bolt and nut connections, its superficial form is converted to the simplest form of a truss, thus applying less parts (T5) as well as multiple bending and pressing are d in joist components, hence its lower chord is made of channel section or steel sheet with proper width and thickness (element 2 in T5) with tensile performance, and the upper chord used in it is from channel section (element 1 in T5) which has appropriate gyration radius on both directions with compression performance, and vertical middle chord is made of a rebar with compression performance (elements 3 and 4 in T5), and due to special shape of joist and form of the parts, the joist could be executed with different types of permanent and provisional molds such as expanded polystyrene, provisional wooden mold, galvanized sheet etc.

Replacing middle chord as stud and omitting extra screw in connections: By making use of thread on both ending sides of middle chord and passing it through the holes made by punching device in the upper and lower chords and by fastening nuts on the two ending points of the middle chord (SECA and SECB), the threaded place acts as a bolt in the connections, and along with the middle vertical chord upwards and fastening the nut at its end (SECA), we may provide performance of stud in it without any need for welding or screwed the stud to the ceiling.

Advantageous Effects of Invention

1- The privileges of our asserted invention are concerning optimization of the joists with nut and bolt connections which the following points are attention.

2- Providing integrated stud of joist.

3- Capability of executing joist with type of permanent and provisional molds.

4- Omitting extra bolt in joist connections.

5- Decreasing construction expenses due to deleting bending and pressing on various parts and more convenient production procedure due to simplification in truss of the joist and making use of minimum consuming iron regarding the new design.

6- Higher speed in assembly process.

Deion of Embodiments

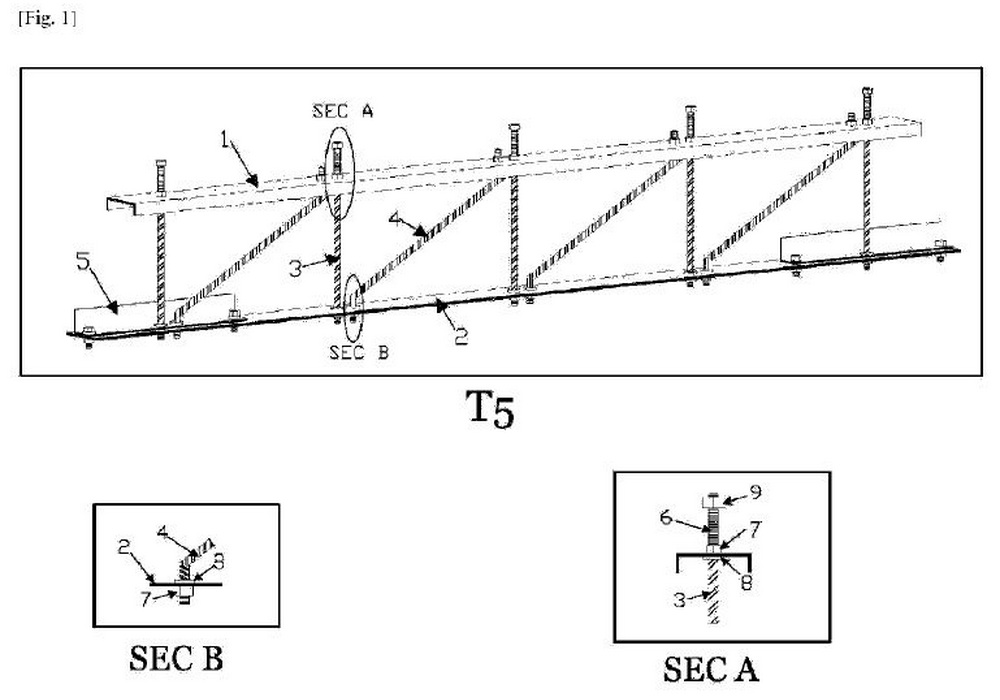

T5: is general schematic of composite joist with integrated stud of joist without welding in connections of joist.

SEC A: Element details of the lower part of joist in T5.

SEC B: Element details of the upper part of joist in T5.

Element 1 in T5 includes: upper chord of joist made of channel section or by making use of any kind of proper section and applicable in such a way that radius of its gyration are supplied on both sides which are perforated with equal distances and are regarded as compression elements.

Element 2 in T5 includes: lower chord of joist made of types of steel sheets with required width and thickness in length which could be strengthened with other elements such as angle, channel etc. or by making use of any kind of authorized section and applicable in such a way that the radius of gyration are provided on both sides which are punched with equal distances and are considered as tensile elements.

Element 3 in T5 includes: vertical part of middle rebar whose both ends are threaded and repeated along with joist with equal distances, and since no welding has intervened, we may use types of high-resistant rebars with various diameters and dimensions and they are regarded as compression elements.

Element 4 in T5 includes: diagonal part of middle rebar whose both ends are threaded and they are repeated with equal distances along with joist, and since no welding has intervened, we may use types of high-resistant rebars with various diameters and they are regarded as tensile elements.

Element 5 in T5: for shear controlling due to sitting in place could be used in the form of angle or channel and/or application of any kind of authorized and applicable section is used with bolt and nut connection.

Element 6 in SEC A: which is along with element 3 in figure T5 in order to provide stud on the applied joist.

Element 7 in SEC A & SEC B: Place of installing nut.

Element 8 in SEC A & SEC B: Place of installing washer.

Element 9 in SEC A: Place of installing nut for stud performance.

Production line, regarding construction procedure

1- The line of transferring parts to automatic cutting machine to supply required consumption lengths.

2- The line of transferring channel and strap in the place of punching machine in order to make required holes with definite distances.

3- The line of transferring cut parts of rebar to bending machine to provide appropriate angle at the end of diagonal rebars.

4- The line transferring cut parts of rebar to rolling automatic machine in order to thread two ends of the rebars.

5- Assembly line of connecting all parts by nut and washer together manually or automatically.

6- Production line of painting joist manually or automatically.

7- Packing and sending joists.

It should be mentioned for sending the product in bulk conveniently, we can sent the parts separately and execute (2) in the site of project.

Industrial Applicability

It is used in execution of types of ceilings in types of residential, administrative, industrial and commercial structures and also upon execution of deck ceiling and composite with types of permanent and provisional molds in various type of structural carcass.